Check Valve

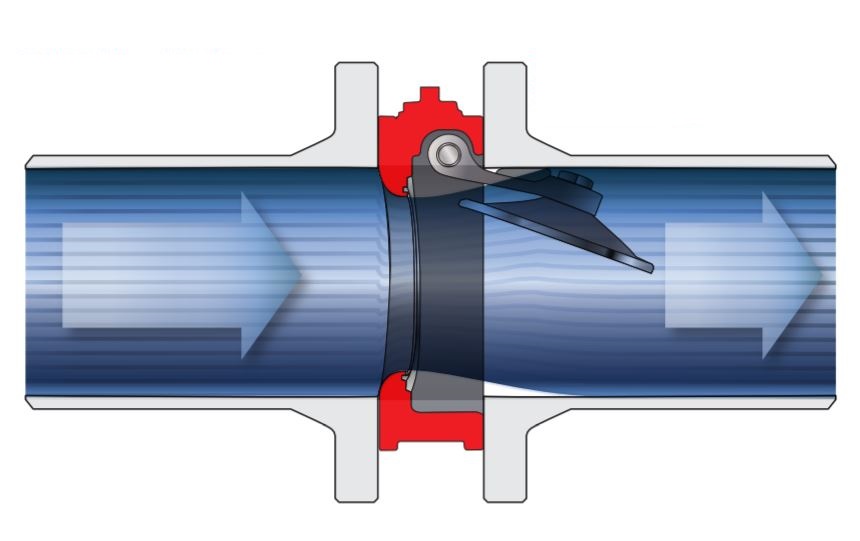

A check valve is a type of valve that allows fluid to flow in one direction only. If you’ve ever used a faucet with two handles, one handle controls the flow of water through the spout and the other handle controls whether or not water will drain down into your sink. The handle for draining water is called a shut-off valve because it shuts off or stops the flow of water from your faucet. In this way, it works like a check valve—one way only!

Check valves are used across many industries

Check valves are used in many industries, such as plumbing systems and air conditioning systems, to prevent backflow or reverse flow. This prevents contamination from entering into your pipes or cooling system via pressure differentials (i.e., hot and cold pipes) caused by changes in elevation between locations where hot/cold fluids enter/exit buildings).

Check Valve installation

Check valves should also be installed on sprinkler systems so water flows only downwards when a fire breaks out; if there was no check valve on each sprinkler head then fire fighters would have difficulty putting out fires as they would constantly be fighting against rising levels of contaminated water being released from malfunctioning sprinklers!

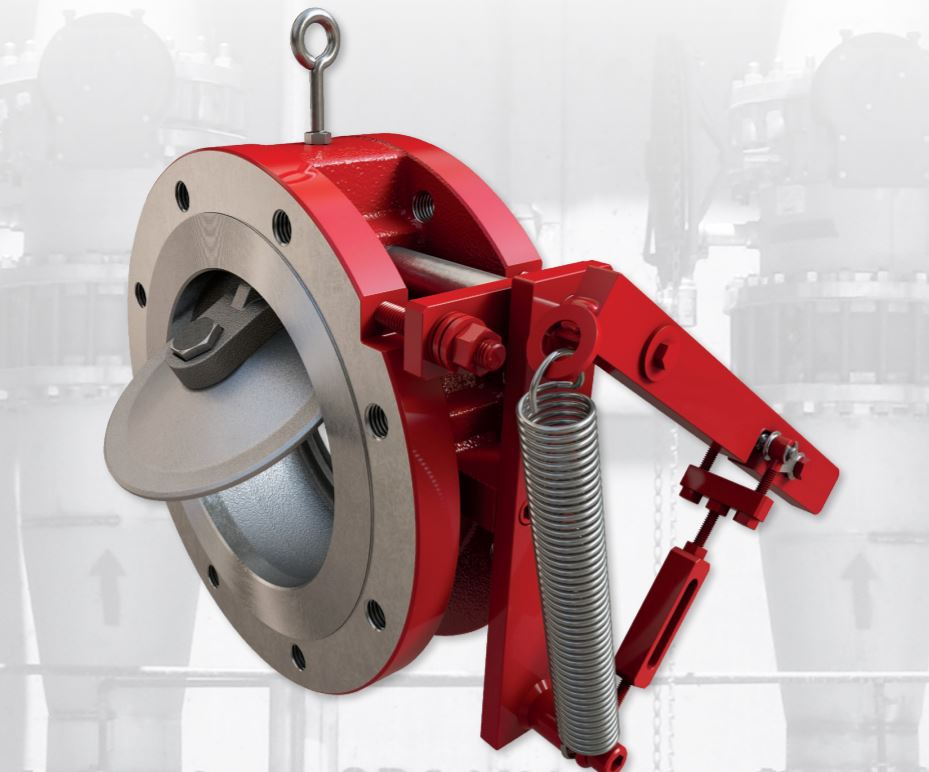

SlurryTuff™ and Bray/Rite check valve design

SlurryTuff™ and Bray/Rite check valve design continue to be the premier wafer combination swing check valve. De-signed in 1970, their performance remains unsurpassed. The line offers a wide range of valves and accessories, all fully stocked and readily available. Their successful, long-term use in applications worldwide has made the Bray/Rite the industry standard for economy, durability and reliability.

State of the Art Check Valves

Wafer combination swing check valves are flow–activated and RiteSized. Bray/Rite inlet ports and disc have been shaped and optimized to achieve a fully open position at low flow rates (3 ft/s on average). Therefore, the Bray/Rite operates exceptionally well in the flow rates typically found in pipelines containing control valves and lines with varying media flows.

Zero Leakage

Bray/Rite valves, either resilient or metal seated, offer zero leakage in all pressure classifications. Each valve is hydrostatically tested at the factory and shipped with a certificate of compliance to MSS SP61.

Rite has achieved zero leakage metal-to-metal sealing by a proven, engineered design backed by high-quality manufacturing craftsmanship. As the disc closes toward the seat, the increased velocity of the line media and the unique shape of our seat remove all particles from the sealing surfaces – ensuring zero leakage.

Low Pressure Drop

The low pressure drop of the Bray/Rite valve was achieved by Rite’s many years of research and development in combination with universities and federal research agencies. Several theses and papers were published, including Minimizing the pressure loss of wafer type swing check valve ASME 79/MA-NE-5. These results – primarily the optimum valve diameter and elliptical inlet shape – have been incorporated into the Bray/Rite design. Like a venturi, the aerodynamic shape accelerates the line media through the valve with the lowest possible pressure drop. Pressure drops at the full open position are between 0.5 to 0.7 psi for all size valves. Additionally, the disc shape and mass have been optimized to use the pipeline media flow as a lifting force on the disc, thus allowing a full open valve position in low line velocity.

High Flow Capacity

Bray/Rite’s valve inlet is an elliptical shape and optimum diameter, plus its virtually unobstructed opening combines to produce a substantially higher flow capacity (Cv)than other wafer combination swing check valves.

Reduced Water Hammer

An additional focus ofRite’s R&D program was linked to Water Hammer Prediction. Findings were applied in the design of the valve to largely reduce or eliminate water hammer by closing the valve at the right moment (before reverse flow occurs). The Bray/Rite uses gravity, assisted by an internal spring, to pull the disc toward the closed position on decelerating line media flow. Rite has developed proprietary predictive software to select the best solution for your specific application. The disc’s angle and shape allow fluid to travel faster around the disc, thus creating lift like an aircraft wing.

Seats

Zero leakage shut off, even at 0 psi, is achieved through lapped metal seating surfaces. The seat and the disc edges are precisely machined and then hand polished for a perfect fit. The disc hinge provides an even force at the disc to seat contact point, ensuring a uniform seal. Controlled tolerances maintain the proper disc to seat alignment. The spring-assisted closure tension holds the disc in place when line pressure is removed.

Resilient Seat

A dynamic, O-ring seat is contained in a specially designed body groove. As line pressure is applied, the valve disc uniformly compresses the seat into the groove, ensuring a zero leakage seal. The seat is easily replaced, simplifying maintenance.

Metal-To-Metal Seats

Integral metal seats feature an engineered and precision machined angle that minimizes the metal-to-metal contact point between the disc and seat for a perfect seal. Pressure is applied evenly over the disc, eliminating galling and reducing wear.

Metal Seat Insert

Carbon steel and ductile iron bodies have a stainless steel seat inserted into the body seal area, offering the same precision design as the integral metal-to-metal seat. These bodies are also available with a Resilient Seat Insert.

InherantlyFire Safe

Bray/Rite valves are inherently fire safe due to the valve design, materials and construction. In the event of a pipeline fire, both resilient seated and metal seated valves provide metal-to-metal contact between the seat and disc and surpass all leak test standards.

Pumping Cost Savings

Pumping costs have been often overlooked but are now gaining in importance due to the increasing cost of energy. With Bray/Rite’s long service life, its cost is actually insignificant to the end user compared to the energy lost pumping the fluid through the valve. Below is a comparison between different valve styles, assuming all valves are 100% open.

Horizontal / Vertical Installation

Unlike most conventional check valves, Bray/Rite wafer combination swing check valves are ideal for both horizontal and vertical pipeline installation – requiring only a single line for operation. This greatly increases pipeline layout flexibility and significantly reduces costs. In vertical installations, typical swing check valves must have an offset pipe section installed since these valves only function in a horizontal position. See factory for vertical down applications.

Light Weight & Reduced Size

Installation costs are greatly reduced by Bray/Rite’s lightweight and minimal space requirements. Their compact design minimizes the distance between faces and is easily installed between all flanges. Bray/Rite valves do not require added support to maintain pipeline integrity and need only 30% of the space of typical full-size swing check valves.

Related Products