Relief Valves

A pressure relief valve (PRV), also known as a relief valve, is a type of safety valve used to manage or restrict pressure in a system, preventing pressure accumulation that may otherwise cause a process upset, instrument or equipment failure, or fire. Internal pressure can be lowered by sending the pressurised fluid through an extra exit. A relief valve is designed to open at a specified set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limitations.

The relief valve becomes the “way of least resistance,”

When the fixed pressure is surpassed, the relief valve becomes the “way of least resistance,” opening and allowing some fluid to flow into the secondary channel. A flare header or relief header is often used in flammable fluid systems to guide the diverted fluid to a central, high gas flare, where it is burnt, releasing bare combustion gases into the atmosphere.

Fluid is normally discharged to the atmosphere

In non-hazardous systems, the fluid is normally discharged to the atmosphere via proper discharge pipework that is positioned so as not to endanger employees and is intended to prevent rainwater intrusion, which can alter the set lift pressure.

Internal pressure controlled by rerouting the flow

We can keep the internal pressure from rising by rerouting the flow. When the pressure reaches the valve’s reseating pressure, the valve will close. The blowdown is the percentage of the set pressure that must be dropped for the valve to reseat. Some valves include an adjustable range that permits the blowdown to be anywhere between 2% and 20%.

Relief valve outlet in high-pressure gas systems be in the open air

It is advised that the relief valve outlet in high-pressure gas systems be in the open air. When a relief valve is opened in a system where the output is connected to piping, pressure builds up in the piping system downstream of the relief valve. This frequently implies that once the predetermined pressure is achieved, the relief valve will not re-seat.

Differential relief valves

Differential relief valves are frequently employed in these systems. This indicates that the pressure is only acting on a considerably smaller region than the area of the valve’s opening. If the valve is opened, the pressure must drop dramatically before the valve shuts, and the valve’s output pressure can easily keep the valve open. Another factor to consider is that other relief valves linked to the outlet pipe system may open when the pressure in the exhaust pipe system rises. This may result in undesirable functioning.

Bypass valves

Bypass valves are sometimes used as a form of pressure relief by rerouting fluid from where it has been discharged, such as from a pump or gas compressor, back to a storage reservoir or the inlet of the pump or compressor. This is done in order to prevent damage to the pump or gas compressor and any other connected devices caused by an unexpectedly high pressure.

located inside the pump or compressor

Both the bypass valve and bypass path can be located inside the pump or compressor, making them a structural component, or outside of it (installed as a component in the fluid path). Overpressurization of fire hoses is avoided with the help of relief valves, which can be found on many fire engines.

Shielded against internal vacuums (low pressures)

In some situations, equipment needs to be shielded against internal vacuums (low pressures) that are greater than what it can endure. In these situations, vacuum relief valves are used to manage the amount of vacuum by opening at a specified low-pressure limit and allowing airflow or an inert gas into the device.

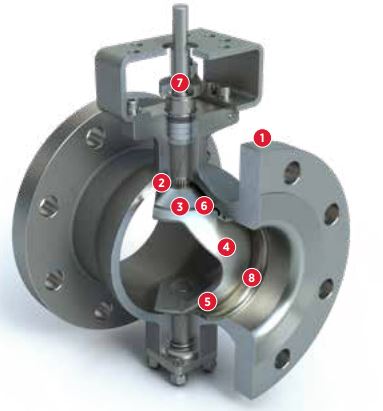

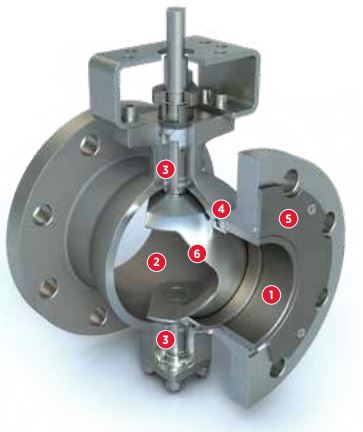

Types of SlurryTuff™ and Bray valves below