Segmented Ball Valve

SlurryTuff™ – Solving your flow control challenges with segmented Ball Valve Design.

Superior Control

Segmented ball valves are designed for modulating

control and on-off services in gas, liquid, and slurry applications.

The Bray Series 19 and Series 19L segmented ball valves deliver

exceptional performance with the precision, features, and

options for superior control in a wide variety of industries

and applications

Custom Characterisation

With 300:1 rangeability, three standard port options, and

available customized characterization, the S19 segmented

ball valve can be designed for optimal flow performance

Features and Benefits

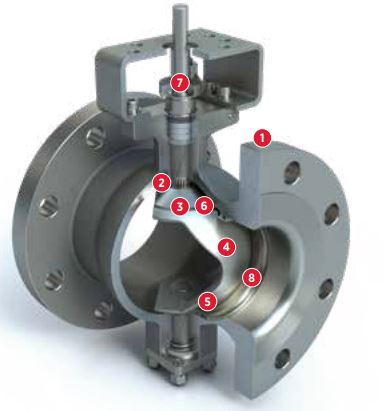

Standard Service | Series 19

The perfect control valve solution for slurries containing suspended solids or fibers, viscous fluids, pulp, paper, chemical,

wastewater sludge, and other challenging service conditions.

Design Features

1 ONE-PIECE BODY: Provides a rigid, robust shell

capable of withstanding pipe loading, and eliminates

potential leak paths.

2 SPLINED STEM TO SEGMENT CONNECTION: Provides

efficient torque transmission and precise control, with

low hysteresis and reduced deadband.

3 SELF-CENTERING BALL SEGMENT: Perfectly oriented,

specially designed shaft pin facilitates self-alignment

of the ball segment, while simplifying assembly and

disassembly during routine maintenance.

4 COATINGS: High-performance coatings on internal

components ensure long life and corrosion resistance.

5 ENERGIZED SEAT: Seat spring provides constant

force on the seat to seal against the segment at low

differential pressures. At higher differential pressures,

optimized sealing diameters ensure lower seat torques.

6 PROTECTED SEALING AREA: Seats are designed to

direct media flow away from the sealing area.

7 BLOWOUT PROOF STEM: Retaining ring fits between

machined stem groove and gland retainer step.

8 EASY MAINTENANCE: The seat is replaceable without

removing the segment and shaft.

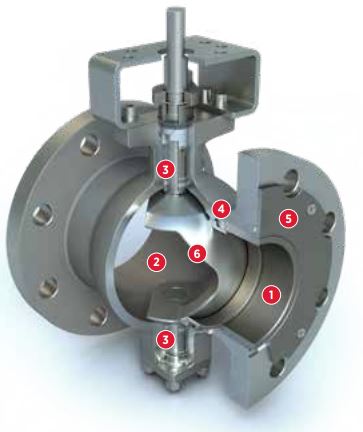

Server Service | Series 19L

Severe erosion demands more from your control valve. In addition to the benefits of the standard service valve, the S19L offers

advanced material selections and multiple trim options to provide an application-specific solution for your unique needs.

Design Features : Segmented Ball Valve

1 EROSION RESISTANT DOWNSTREAM LINERS/SEATS:

Reverse flow direction prevents body wall erosion due

to high velocities at low openings.

2 SEVERE SERVICE COATINGS: Customized ultra-hard

coatings provide application-specific corrosion and

erosion resistance for valve internals.

3 BEARING SEALS: Protects metal bearings from ingress

of media.

4 PRESSURE BALANCED SEAT DESIGN: Seats capable

of sealing under full differential pressures with low

torques and smooth operation.

5 EASY MAINTENANCE: Flanged retainer provides easy

external access for seat and liner replacement. Seat is

replaceable without removing the segment and shaft.

6 TRIM OPTIONS: Multiple options available for

optimized performance in various levels of erosive

services

Control Valve Center Of Excellence

Extensive research & development is a key component in Bray’s formula for

providing optimized flow control solutions. Ongoing activities at our Control Valve

Center of Excellence include:

> Controls, automation, and actuation

research

> Advanced coatings research

> Electronics research & IIOT

> Metallurgy

> Hydraulics

> 3D Printing