Pipeline Valves

Pipeline Valves: Essential Components for Efficient Fluid Flow

As a prominent figure in the industry, we bring you valuable insights into the world of pipeline valves, shedding light on their diverse types, functions, and the pivotal role they play in maintaining optimal fluid flow within pipeline networks. From our years of experience, we understand that the proper functioning of pipeline systems is reliant on the precise regulation of fluid movement. This is where pipeline valves come into play.

With this comprehensive write-up, we will delve deep into the intricacies of various valve types and their applications, revealing how they contribute to the seamless operation of pipelines, whether in gas transmission, fluid control, or emergency shutdown scenarios.

As we navigate through the different valve types, their functions, and the factors influencing their placement, you’ll gain a comprehensive understanding of how these unassuming components have a profound impact on the world of industrial fluid transportation.

Types of Pipeline Valves

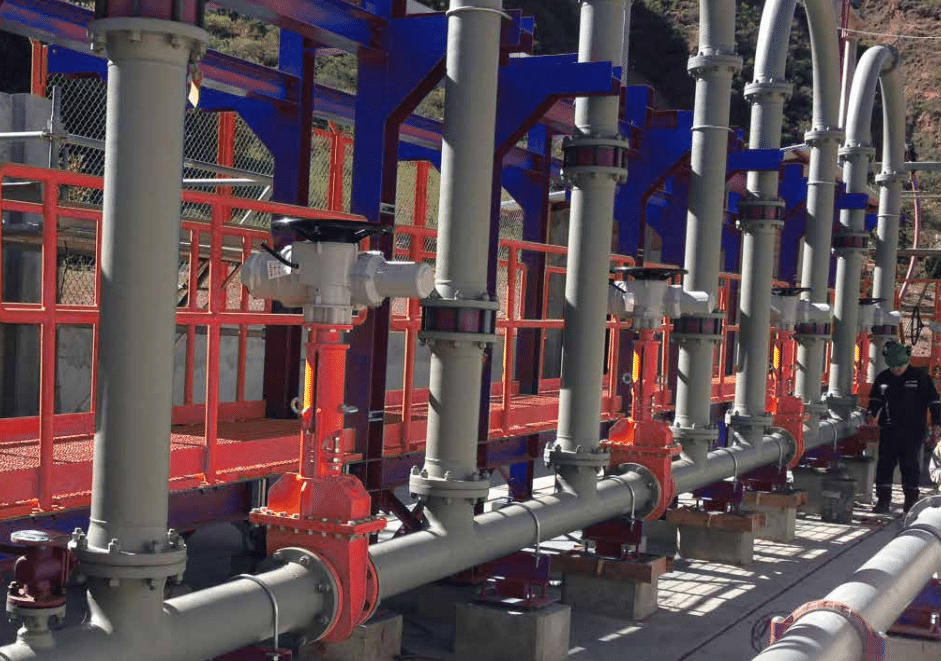

Gate Valves

Gate valves are among the most common types of pipeline valves. They function by lifting a gate out of the path of fluid flow, allowing for unrestricted passage. SlurryTuff™’s gate valves are engineered to provide exceptional sealing and longevity.

Ball Valves

Ball valves employ a spherical disc to control flow. When the valve is open, the bore aligns with the pipeline, enabling swift flow. Our ball valves are known for their reliability and ease of operation.

Plug Valves

Plug valves, including lubricated plug valves, use a cylindrical or tapered plug to regulate flow. These valves are ideal for applications where tight shut-off is essential.

Control Valves

Control valves manage fluid flow rate by varying the size of the flow passage. They are integral to maintaining precise control in various industrial processes.

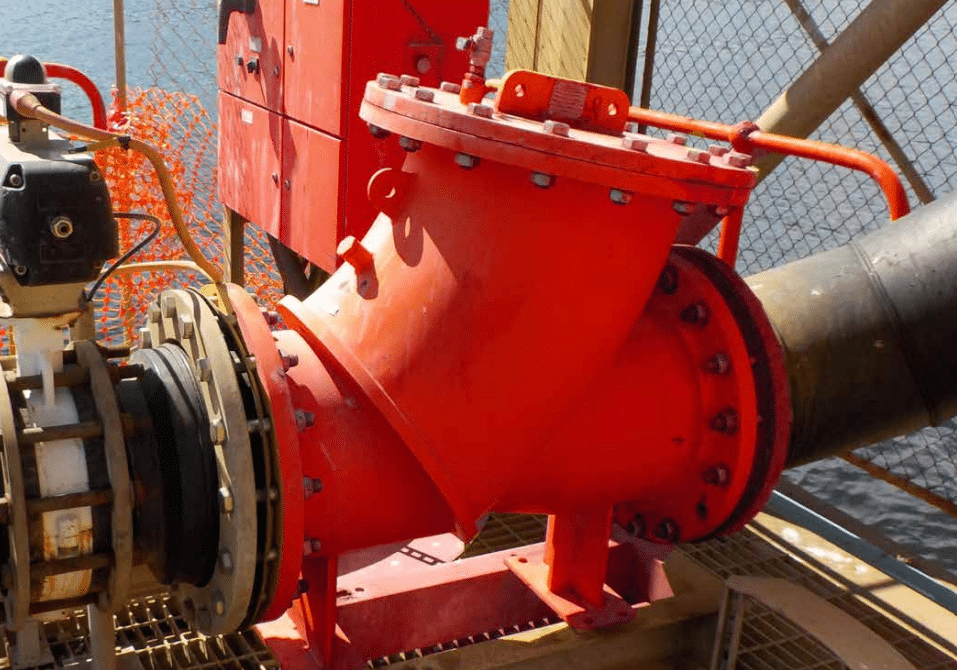

Check Valves

Check valves permit one-way flow, preventing backflow and protecting equipment. SlurryTuff™’s check valves are designed to ensure fluid flows in the desired direction.

Needle Valves

Needle valves offer controlled flow adjustment in low-flow situations. They feature a slender, threaded plunger that allows for fine-tuned flow regulation.

Butterfly Valves

Butterfly valves use a circular disc with a pivot to control flow. They are lightweight, cost-effective, and well-suited for large-scale operations.

Globe Valves

Globe valves employ a movable plug against a stationary ring to manage flow. They provide accurate control over flow rate and are commonly used in fluid-handling systems.

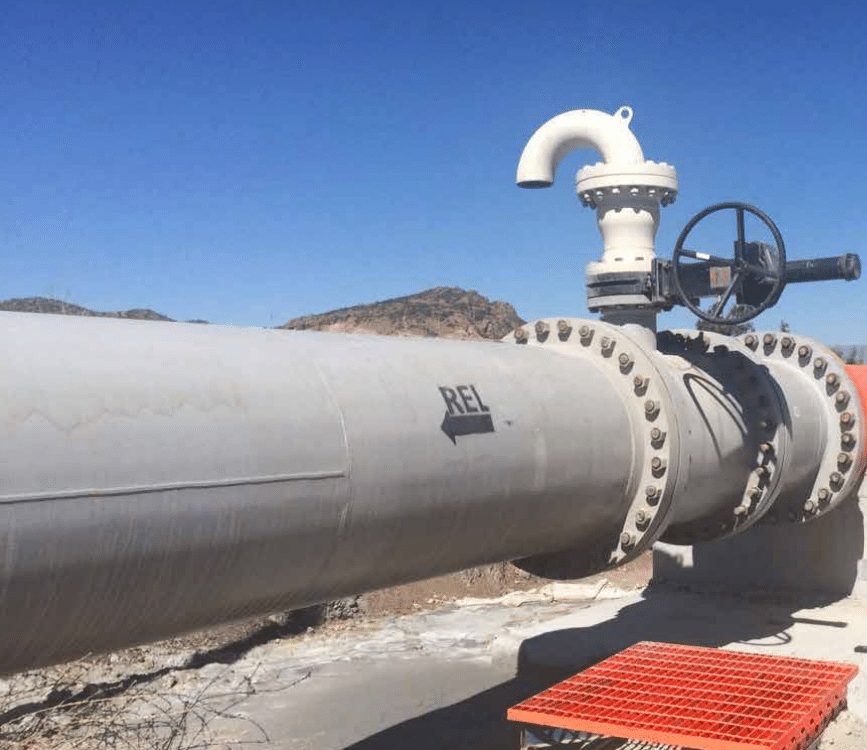

Relief Valves

Relief valves prevent excessive pressure buildup in pipelines, safeguarding the system from potential failures. SlurryTuff™’s relief valves offer dependable overpressure protection.

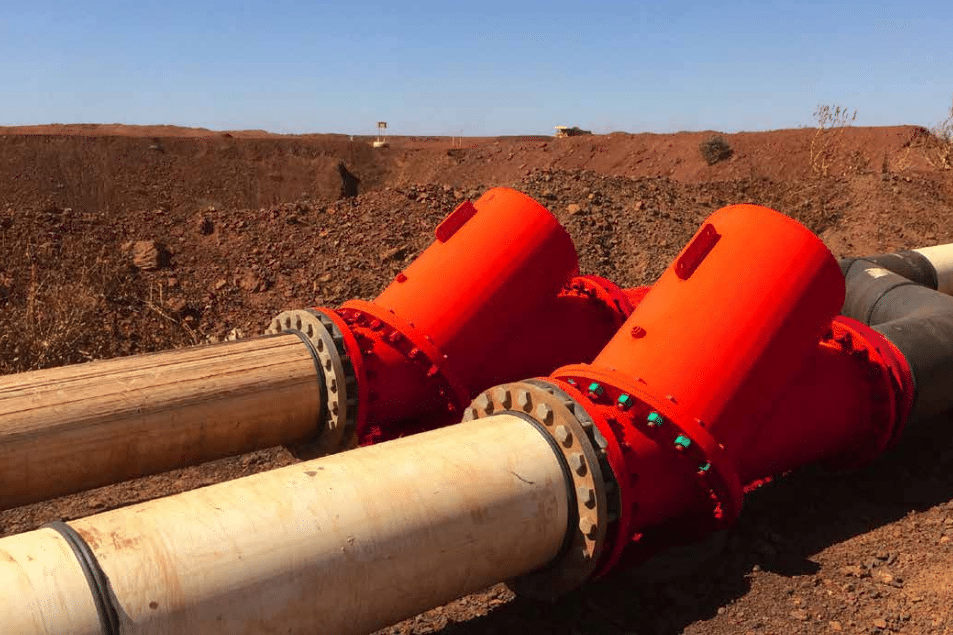

Emergency Shutdown Valves

Emergency shutdown valves are crucial for preventing catastrophic events. They ensure rapid closure in critical situations, protecting both personnel and equipment.

Pipeline Valve Functions

Pipeline valves serve various functions within a fluid transmission system. They enable control over flow rate, pressure, and direction, allowing operators to manage the movement of liquids and gases effectively. Their diverse functions ensure efficient operation, system integrity, and safety. In this section, we delve into the multifaceted functions that pipeline valves fulfil, illustrating how they contribute to the overall performance of these vital systems.

Start and Stop Control

One of the fundamental functions of pipeline valves is to initiate and halt the flow of fluids. By opening or closing the valve, operators can instantaneously start or stop the movement of liquids and gases through the pipeline.

Flow Rate Regulation

Precise control over the flow rate is essential in diverse industrial processes. Pipeline valves allow operators to adjust the opening of the valve, thereby regulating the amount of fluid passing through the pipeline.

Pressure Management

Pipeline systems often encounter variations in pressure due to factors such as elevation changes, fluid viscosity, and friction. By adjusting the valve’s settings, operators can ensure that the pressure remains within safe operating limits.

Redundancy and Backup

Many pipeline systems incorporate redundant valves as a safeguard against valve failure. These backup valves can take over in case of primary valve malfunction, ensuring uninterrupted fluid flow and system reliability.

System Balancing

Valves are essential for balancing fluid distribution within a network. By adjusting the flow rates at various points, operators can equalise pressure and optimise the performance of the entire system.

Factors Influencing Valve Spacing

The strategic placement of pipeline valves is a critical aspect of designing and maintaining efficient fluid transmission systems. Valve spacing directly impacts the system’s performance, maintenance ease, and overall reliability.

Pipe Diameter and Flow Rate

The diameter of the pipeline and the anticipated flow rate play a crucial role in determining valve spacing. Larger pipelines with higher flow rates may require more frequent valve placement to ensure optimal flow control, while smaller pipelines may have fewer valves due to their lower capacity.

Fluid Characteristics

The properties of the fluid being transported influence valve spacing. For instance, corrosive or abrasive fluids may require more frequent valves to mitigate potential damage, while non-corrosive fluids might allow for longer spacing

between valves.

System Design and Layout

The layout of the pipeline network is a key determinant of valve spacing. Complex systems with multiple branches or intersecting pipelines might necessitate more valves to ensure precise control and fluid distribution.

Maintenance Accessibility

Valve spacing should consider ease of maintenance. Placing valves at accessible points allows for efficient inspection, testing, and repair. This is particularly crucial for minimising downtime and ensuring system integrity.

Environmental Considerations

The environment in which the pipeline operates can influence valve spacing decisions. Harsh chemicals, seismic activity, or exposure to extreme temperatures might necessitate closer valve spacing for enhanced safety and durability.

Conclusion

In conclusion, pipeline valves are integral components of fluid transmission systems, allowing for efficient flow control and system safety. SlurryTuff™ offers a comprehensive range of high-quality valves, including gate valves, ball valves, plug valves, and more. Achieving the right balance between optimal flow control, maintenance efficiency, safety, and cost-effectiveness requires a thorough understanding of the pipeline’s specific requirements.

At SlurryTuff™, our experience in the industry guides us in offering tailored valve solutions that align with your pipeline’s unique needs. By carefully considering these influencing factors, engineers can design pipeline systems that operate smoothly, reliably, and in compliance with industry standards.